Tuesday morning is not time-boxed, as I am waiting for a shipment. Usually, Tuesday morning means taking Air VW the Gray to Portland in slow-moving traffic to Richard’s house. Today, I have a 3D Printer and various devices for tank 3D printing arriving. I went all-in for the Egloo Saturn 4 Ultra 16K 3D Resin printer and the Mercury XS supporting washing and cure station. I added a metal funnel to pour the resin back into the bottle with a built-in screen. I ordered the support items too. Not quite an all-in step, but I bought the leading edge of the vendor I have used.

I spent the morning writing the blog and skipping breakfast. I had a bagel the night before and was not hungry. I sent a postcard to Mom Wild; I write her every day when there is a post. This was a card I found, a watercolor of the slightly older look of Portland before the recent tall buildings—1990s look—in the fun shop, Crafty Wonderland, in Portland, when I was early for the symphony and walking downtown to get some steps and to look for new places.

I showered, dressed in a red T-shirt, and had suspenders to keep my light brown slacks from letting my pants slide too far. I did discover that the extra-long T-shirts would be a good idea with suspenders! Still trying to like these.

Later, in a church Zoom meeting, with the red shirt and suspenders, I was suggested to start on the beard to prepare for the matching red suit for the holidays. I am trying to resist the family tradition of playing St. Nick, but we will see! I am also thinking maybe the Goth folks may need some Winter Solstice support and get an all black suit with many patches, plus tinsel, and give out fortune cookies for the happy dark and weird folks–just a thought, “Happy Winter Solstice and Merry Christmas; May your wishes be granted.”

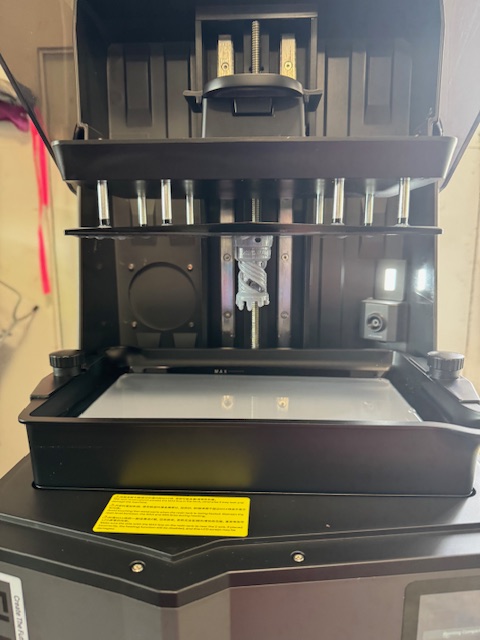

Returning to Tuesday’s story, the printer arrived, and I had the heavy printer and other boxes carried near the garage. I then disassembled the old Egloo printer, which only works on warm days (something I finally discovered). I moved it out of the way and made room for the new, larger, and improved printer. This new model incorporated all the fixes for issues from previous models over the past five years. I also wanted it before the tariffs catch up with costs. Most importantly, this one includes a resin tank heater and careful watching of the temperature by the printer software.

The 16K is the new one.

Unpacking is stressful; you don’t want to drop or scratch anything, and I am looking for delivery damage. I got the Egloo Saturn Ultra 4 16K out of its box, unpacked it, and carried it to a table (a sewing machine table I use as a work table) without discovering damage or causing any.

The printer screws are all Allen wrench slotted. A sticker on the printing plate said to tighten the screws, and I did. I removed the additional packing and replaced the screws that held the tank in place for shipping with nob screws to allow easy removal of the tank. I soon powered up the printer, and the 24V 6A transformer showed the new higher power requirements. The stepper motors and heaters would require about 12V and 2A alone. The computer would be 3.3 or 1.8 V, and 3.3V for lights and camera. It appears to be single-threaded, meaning it is a microcontroller chip refitted to a custom board. All good. We need to be past the Arduino experimental hardware. I did notice that only one motor runs at a time. Someone learned that the drain is harsh, but when you stop/reverse a motor, there is a reverse power flow (like regenerative braking in an EV or Hybrid) and that power can flow and scrambled signals–doing that with two different motors at the same time could be exciting; I have learned that many times! In old tube radios, the lower DC voltage would be sent with a high AC voltage, and then the AC was filtered out to reduce the amount of copper and connections; wild! The comfort level those 1900s engineers had with various voltage signals intermixed is something you don’t see now.

I spent the afternoon installing the hardware, including the other cleaning and curing stations. I also roasted a chicken with veggies. I find chicken a bit plain, but this can be corrected with more salt (this chicken was not pre-prepared with salt—something to always check). I rubbed Kosher salt inside and under the skin of the breast. It helped. The potatoes, placed under the chicken, did not finish in 90 minutes at 350°F; a few minutes in the microwave completed them.

I got the first print when Corwin stopped by for his package (he still has them delivered to the house) and enjoyed the roasted chicken. He thought it was good. I roasted it for an hour in a pot with the lid off, added a cup of water, covered, and let the steam get everything done for thirty more minutes.

I broke the chess piece trying to get it off the print plate—a familiar issue. I will be more careful now. I used my cleaning and curing stations, and they were wonderful. I can repair the figure. Corwin headed out.

I realized I could also use the cleaning station to clean my tools. Excellent. Next, I downloaded an Eiffel Tower STL and combined it with an STL of my custom figure. I used the new software supplied to create a goo file. Egloo now has its own control language, goo. I put that on a memory stick, the printer came with one, and the rook chess piece goo file on it, and printed it.

Disaster! The print pooled and poisoned the resin with floating bits. F**k. I cleaned up the printer and then cleaned the tools and protective glasses. I use masks and gloves for this work. I filtered the resin with my new funnel and cleaned the tank. I re-created my goo with supports and lying Carter on the side (Corwin’s recommendation). I started, and the printer said the resin was still poisoned. I refiltered it and found a bit still stuck to the tank. I wiped out the tank. I reset it, and again the printer said the resin was poisoned.

I had to stop and enjoy the church council meeting. This was a Zoom meeting, and while not as fast-moving as I wished, it was without controversy and fast for Methodists. A replacement sign for the smaller sign was discussed, and a design was offered. It was not loved, but it did not cause any strong reaction to not replacing the sign. It was agreed in principle.

With the meeting over, I will miss the next one. I returned to the printer. As I suspected, the problem cleared. The alcohol I used to clean the printer had not completely dried, causing the fault. I started the print and checked it a few hours later, and it was perfect from what I could see. The base of the Eiffel Tower stuck to the printing plate with the supports. Carter’s figure, now sideways and covered in supports, was forming.

By 10, I was tired and dragging. I went to bed, soon slept, and woke twice to prove hydration.

Thanks for reading!